Precision components for aerospace, automotive, and other applications must be inspected throughout production for damage, and throughout their life span for wear, corrosion and defects.

Inspectors face challenges in determining the severity of defects and the depth of desired features such as laser marking or dot peening. Visual comparison techniques are quick and inexpensive but are subjective and not repeatable. More accurate metrology systems are typically too expensive, slow and susceptible to environmental factors for use on the shop floor.

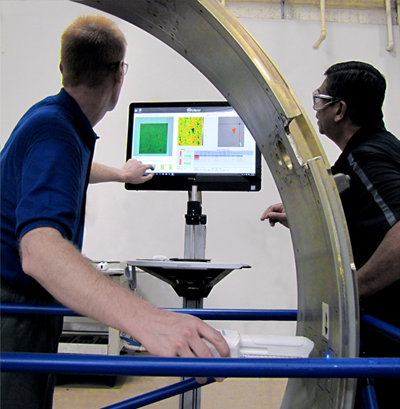

The 4D InSpec Surface Gauge is the first handheld, precision instrument for non-contact measurement of surface features and defects, with micrometer-level resolution. The gauge measures defects from 0.1 to 100 mils deep, even in difficult-to-access areas such as under flanges, in bores and on curved surfaces. Measurements take just seconds, with instant results and reporting.

In this webinar we discussed the Polarized Structured Light (PSL) technology behind the 4D InSpec Surface Gauge. We demonstrate how the 4D InSpec can be used to measure surface features on large components and in difficult to access areas, as well as to make repeatable QA/QC measurements on production parts.

The webinar was held Thursday, Jan 19, 2017.

Registration for this event is closed.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@nanometrics.com

Office Hours (Arizona Time)

Mon: 8am – 5pm

Tue: 8am – 5pm

Wed: 8am – 5pm

Thur: 8am – 5pm

Fri: 8am – 5pm

Sat: Closed

Sun: Closed

Send a Message