Measuring edges and corner radii with 4D InSpec

In this measurement of a curved radius edge, we drew several profile traces at different angles, demonstrating how traces that aren’t perpendicular report the incorrect radius of curvature—demonstrating the hazard of relying on a 2D measurement.

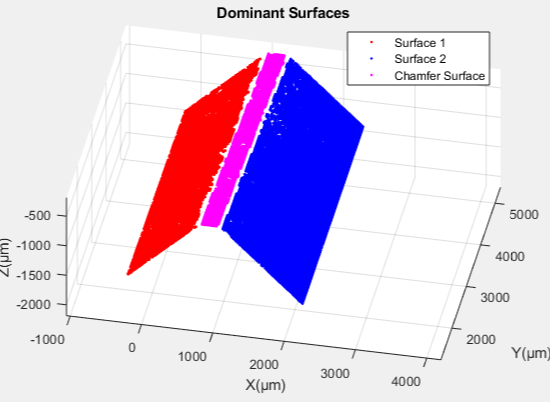

Using a smart algorithm, analysis software can plot regions, which then serve as averages.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@nanometrics.com

Office Hours (Arizona Time)

Mon: 8am – 5pm

Tue: 8am – 5pm

Wed: 8am – 5pm

Thur: 8am – 5pm

Fri: 8am – 5pm

Sat: Closed

Sun: Closed

Send a Message