Machined Components

Precision machined components are fundamental in applications from aircraft engines to MEMS devices. The machined surfaces of these components may serve a variety of functions, including sealing, oil retention, cosmetic appearance, etc. The surfaces of optical grade mirrors and actuating structures of MEMS (Micro-Electro-Mechanical Systems) devices also fall into this category. In all cases, understanding the surface texture of the functional surfaces is critical for proper performance.

Many methods are available for measuring surface texture on precision components. The methods tend to divide into two categories: low-resolution yet easy-to-use systems, and higher end 3D measurement systems with higher resolution but more limitations on the components that can be measured. Inspectors are often faced with a trade-off between ease of measurement versus higher-resolution, repeatable measurements.

In many cases, the higher resolution systems are simply not an option. Large components, or components with flanges, small radii, blind holes and other difficult to access features also prove challenging to measure with sufficient resolution.

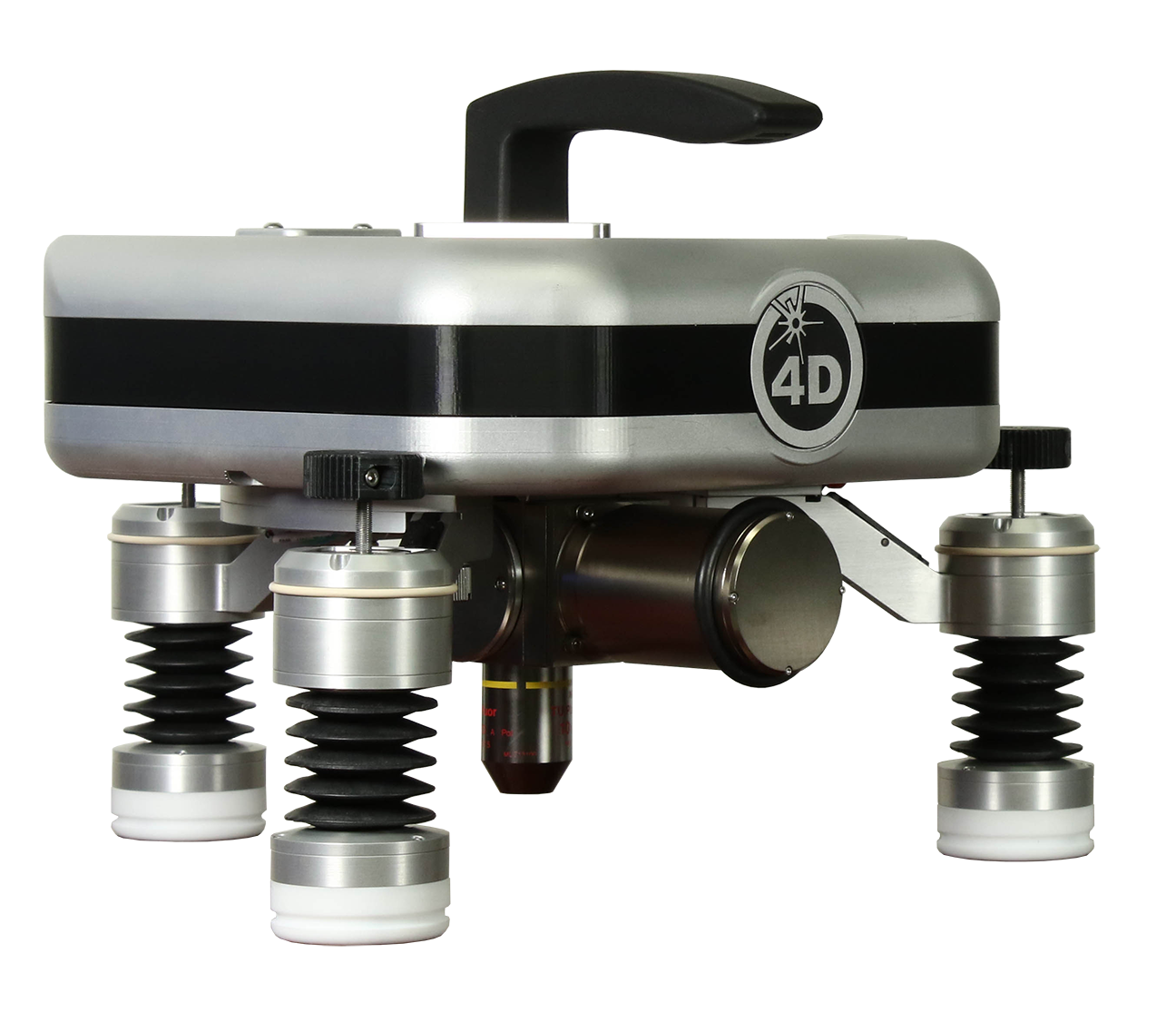

The 4D InSpec Surface Gauge measures surface defects, as well as fine features such as rivet depth and dot peening, right on the factory floor. Fast, portable and easy to learn, the 4D InSpec is the world’s first handheld, high resolution surface defect measurement system.

Added Technical Resources

Measuring MEMS and other vertical roughness surfaces

A new technique provides a faster, more repeatable method for vibration-insensitive measurement in non-ideal environments.

Measuring Surface Features with High Resolution in Factory Environments

This article from Industrial Photonics magazine illustrates how the ability to measure surface defects and features anywhere in the factory or on the flightline can be a transformative change in quality control procedures.

Measuring Sub-Angstrom Roughness

How do you measure roughness with sub-angstrom precision in a noisy manufacting environment?

Read this white paper for a break-down of the options, and illustrations of the challenges presented by different solutions.

Products for Precision Surface Measurement

Optical Profilers

NanoCam HD systems measure surface roughness on coated and uncoated precision surfaces to ensure the quality of polishing processes.

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

Do you need custom-built metrology?

Get a free consultation. 4D Technology’s mechanical, optical, electrical and software engineering teams are standing by to evaluate what it would take to meet your application’s requirements.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am – 5pm

Tue: 8am – 5pm

Wed: 8am – 5pm

Thur: 8am – 5pm

Fri: 8am – 5pm

Sat: Closed

Sun: Closed

Send a Message