Transmitted wavefront

During design and manufacturing, optical systems and lenses are toleranced and tested to ensure the smallest possible performance error. Traditionally, the shape of each lens surface is specified, with the homogeneity of the bulk material assessed earlier in the manufacturing chain.

Lens designs, however, are based on transmission characteristics such as spot size and wavefront error. Measuring the individual surface is not a reasonable facsimile of a performance measurement for the mounted lens.

Surface errors, refractive index inhomogeneity, mounting stress and, on larger optics, gravitational force will all contribute to the overall Transmitted Wavefront Error (TWE). TWE degrades image quality and leads to losses in performance. By placing tolerance on TWE and testing throughout production manufacturers can reduce risk in optical designs and improve performance.

4D AccuFiz compact laser interferometers and PhaseCam Twyman-Green dynamic interferometers accurately measure transmitted wavefront error in flat and focal optics. A wide range of test wavelengths, aperture sizes and accessories accommodate a vast array of optics.

Added Technical Resources

Measuring Transmitted Wavefront Error

A new technique for vibration-insensitive measurement of transmitted wavefront error (TWE) improves repeatability by more than 7X.

Products for Transmitted Wavefront Error Measurement

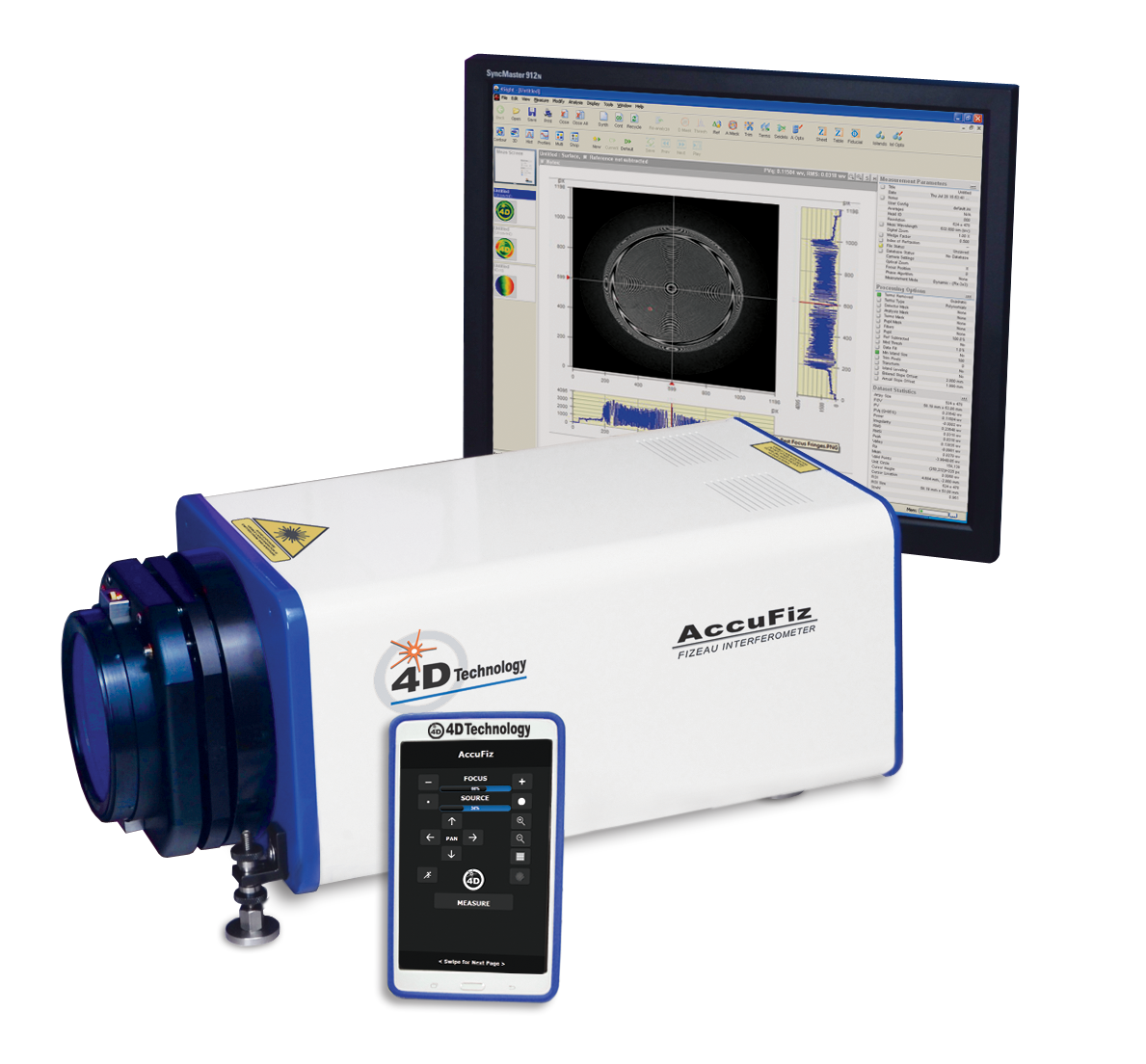

AccuFiz

Excels at fast, repeatable measurement of transmitted wavefront error of flat and wedged optics.

PhaseCam

PhaseCam dynamic Twyman-Green laser interferometers provide high resolution measurements despite vibration and air turbulence.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am – 5pm

Tue: 8am – 5pm

Wed: 8am – 5pm

Thur: 8am – 5pm

Fri: 8am – 5pm

Sat: Closed

Sun: Closed

Send a Message